Informative Articles about Shipping Containers

Used Shipping Containers For Sale

You know your company is looking for a shipping container for sale, and the low cost of used shipping containers may prompt you to go for an “as is” container and call it a day. While the promise of such immediate savings can make the choice of a used container seem like a no-brainer, there are several other factors that can come into financial play.

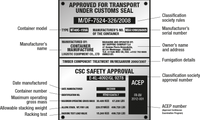

Container Survey Guide

Container Alliance provides containers in many grades from AS IS to One Trip. These containers can be used for storage or shipping depending on condition and documentation.

Container Order Checklist

Now that you placed or are ready to place your order, here are a few things to keep in mind to help with figuring out what is the best location on your property, placement of doors, correct operation of the cargo doors and what to expect on the day of delivery.

Shipping Container Maintenence

So you’ve had your shipping container for a little while now. Over time you might have noticed a few issues that you need to address. We have some tips on how to combat these problems if they ever occur during the life of your container.

Los Angeles Storage Container Rentals

Los Angeles, California is one of the most densely populated cities in the country, and with that comes limited space and an inherent influx of people coming in and out of the city. Is your home or business cramped for space in the Los Angeles area?

SHIPPING CONTAINERS: THE FUTURE OF AGRICULTURE

SHIPPING CONTAINERS: THE FUTURE OF AGRICULTURE

One Trip Container Color Options

Shipping Containers come in many sizes and colors. Below are descriptions of the colors we have available in One Trip Containers along with some added benefits. We can always paint your container any custom color at additional expense if you do not see a color you are looking for.

Refrigerated Container Cost Comparison Diesel Vs Electric

All Electric Container Vs Diesel Trailer

How to care for your shipping container

Your container will last much longer if you follow these steps

Cargo Container Myths

One of the reasons you may not be choosing to use a shipping container for your next project may be a myth. Let’s debunk some of the common myths.